BSM works with a variety of metals including steel, aluminum, stainless steel, and galvanized steel.

Capabilities:

- CAD design and layout

- Shearing: mild steel 3/8" x 8’; stainless steel ¼" x 8’

- Roll Forming or Bending:

- Tubing and Angle Iron

- Sheet steel - 12 GA or 11 GA steel to 4’ long - Bending reinforcing Bar up to 1”

- Pipe Bending – Up to 1” square tubing and 1 ¼” Schedule 40 Pipe.

- Press Brake – Bend sheet metal and plate material 3/8” by 5’, ¼” – 3/16” by 10’ and 1/8” by 12’.

- Punch up to 7/8” holes

- Certified Structural Welders

- Welding:

- Carbon Steel, Stainless Steel, Chromium-Molybdenum, Cast-iron and Cast Aluminum

- Welding Processes: MIG, TIG, Shielded Metal Arc, flux core; at our location

- CNC Plasma Cutting of Aluminum, Steel and Stainless Steel – Up to 1” thick mild steel, 5’ x 10’

- Flame Cutting Processes: Oxygen Acetylene and Plasma

- Oxygen Acetylene Torch process

- Milling

- Turning Capabilities Drilling, Boring and Tapping

- Threading – Ability to thread pipe up to 3” in diameter and bolt threads up to 1 ¼”.

- Drilling – Core and electrometric

- Painting –BSM paint booth, sprayed or rolled (automotive grade paint)

- Grinding, Finishing

- Powder coating

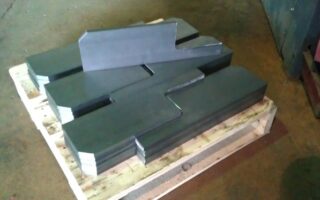

Custom Products

For More Information Call 716-372-6165

| Login